OUR

SPIRITS

Our Core value is to keep receiving "Thank you" from customers

"Thank you DAISHIN-san! It helped!".

The message from our customers is the happiest moment for us.

To hear these voices to meet their requirements thousands, and more, millions of times,

DAISHIN SEIKI keeps improving simultaneous 5-axis machining, high-precision, complex shape, and difficult-to-machine materials.

Also, shorter lead time and lower cost.

This "Thank you" is the "Power" motivating our "Spirits."

Most of our engineers have first-grade national certification.

Also, first-grade national CAD certification.

We keep on developing our engineers and devices.

The passion of our engineers

and our cutting edges equipment fleet

open up endless possibilities.

Advanced Technology

Our technological strength is made possible by linking these three elements - "excellent engineers with national qualifications," "tradition of more than half a century" and "top-of-the-line facilities" - with a passion for manufacturing.

The high quality, short delivery times, and reasonable costs forged through the manufacture of the world's best racing parts that compete for 1/1000th of a second in MotoGP and F1 are currently used to supply high-value-added products in a variety of fields including aerospace parts, defense parts, shipbuilding parts, semiconductor parts, and vacuum parts, not to mention mobility parts.

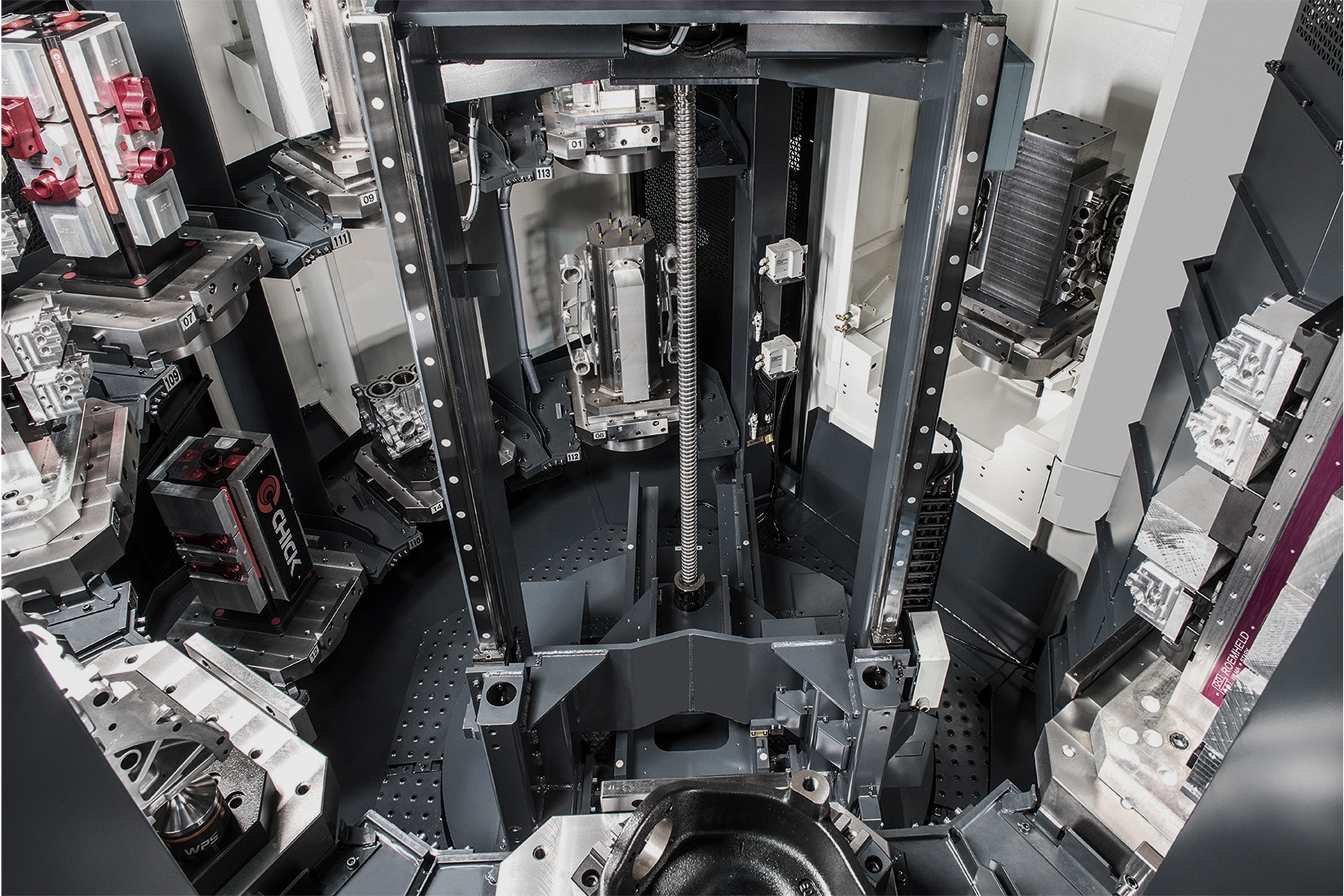

The company owns a large number of high-precision machines, 10 of the latest German-made 5-axis machines, and 8 licenses for 5-axis CAM, and continues to produce high-precision, complex parts that are unimaginable with conventional machining with a high-speed response time.

The company's competence has earned it a high reputation not only in Japan but also in Europe, the home of 5-axis machining.

In recent years, the company has not only developed prototypes, but has also started mass production of small rods through the promotion of automation, and has begun to provide a stable supply of high technical capabilities.

We are also encouraged and proud of the fact that we have Daishin fans all over the world, partly due to the effects of YouTube and SNS.

There is no end to our relentless pursuit and challenge in manufacturing.

We hope you will continue to look forward to the products produced by the skilled team at Daishin Seiki.

Casting Technology

The history of casting is said to date back to 3,600 BC, with bronzes in Mesopotamia, the birthplace of the world's oldest civilization.

In other words, it goes back more than 5,600 years.

Our casting technology has its origins in sand mould casting, which has been handed down since ancient times, and has been improved and refined since the Meiji era,

Even with sand moulds, we provide high-precision thin-walled castings and products with beautifully cast surfaces.

Skilled workers face the products uncompromisingly in each process while implementing stable quality control,

This enables us to offer products with a speedy delivery date.

We handle wide materials including aluminum alloys, cast iron, magnesium alloys, zinc alloys, copper alloys, and cast steel.

Its casting methods range from traditional to state-of-the-art approaches, including raw sand, self-hardening, automated moulding, sand lamination, low-pressure and simple moulds.

Its products are used in a variety of fields, from the world's most prestigious racing parts to prototype openings and small-lot mass-produced parts for major manufacturers.

By combining our cutting-edge machining know-how, we are able to promote improvements and original development that casting manufacturers alone are not able to understand,

We are always ready to make the best proposals for our customers, as well as to explore new technologies.

We create the future by combining traditional and advanced technology.

Quality Organization

We have quality assurance for each of our thousands of components and prototypes every year. We do not allow loss or defects.

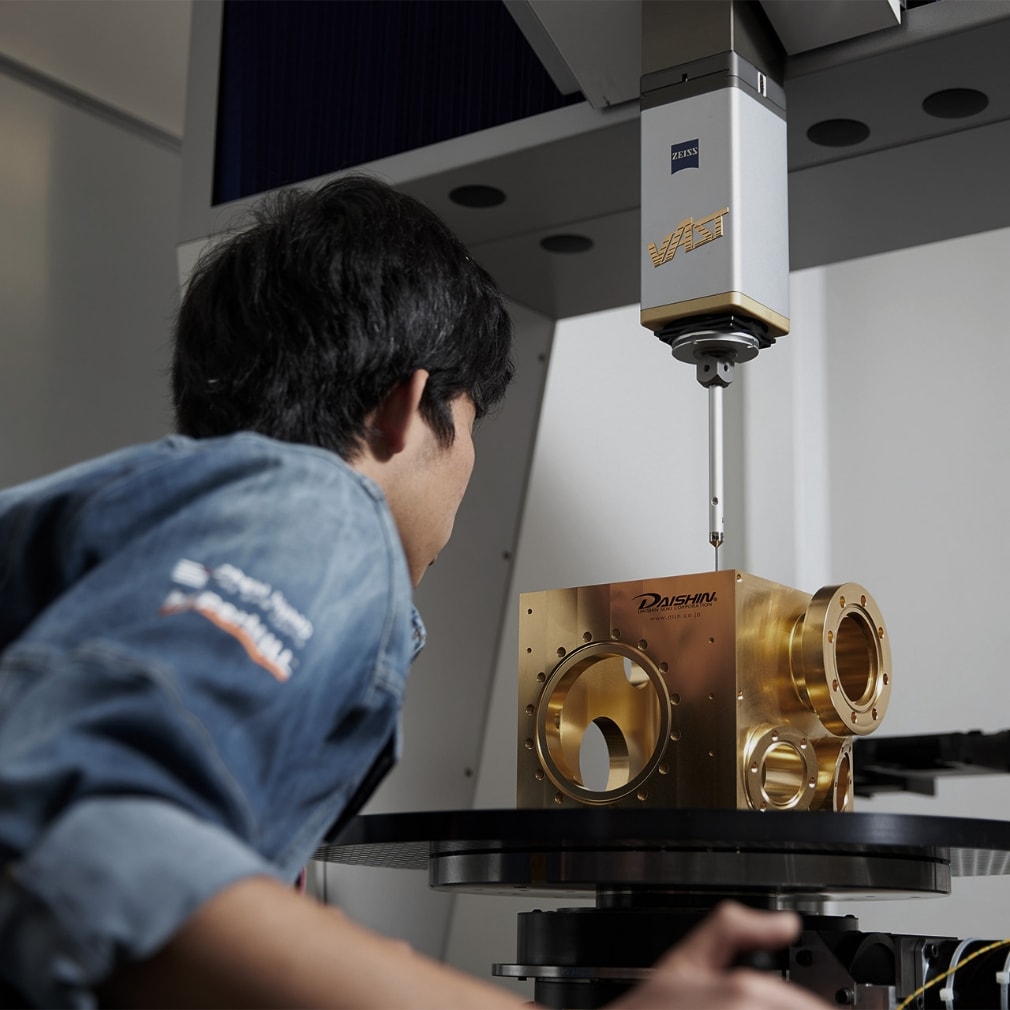

At DAISHIN SEIKI, quality control, and machining are operated by different staff.

Staff are experienced and trained to keep strict quality control and inspection.

In the inspection room, the temperature is controlled within 20 ℃ ± 1 ℃ full day. High-accurate measuring devices such as a coordinate measuring machine from Carl Zeiss and a Cylinder gauge from DIATEST are used. Well-trained and experienced quality control staff makes certain security of DAISHIN. Temporary calibration is scheduled to make stable measurements.

Whatever, quality is made at the point of production. The quality control section adds promises of certain quality and assurance.

Our inspection expert's keen eye to find minute defects plus, our machining expert's pride in high-quality works creates DAISHIN's fine components and products.

The prototypes that pass through this strict quality inspection process can be certified as DAISHIN SEIKI brand.

EQUIPMENT

List of Equipment

RECRUIT

Let's challenge the world

ABOUT US

- Name

-

DAISHIN SEIKI CORPORATION

- Address (Headquarters)

-

4-8-5 Hizaori-cho Asaka-shi Saitama-ken, JAPAN 3510014

TEL +81-48-462-0832

FAX +81-48-464-7842

- South Factory

-

4-8-12 Hizaori-cho Asaka-shi Saitama-ken, JAPAN 3510014

TEL +81-48-458-6336

FAX +81-48-464-7842